Flat Forming Blister Machines

Price 850000 INR/ Unit

Flat Forming Blister Machines Specification

- Usage

- Tablet, Capsule, Ampoule Blister Packaging

- Application

- Pharmaceutical, Food, Cosmetics Packaging

- Filling Range

- Varies by Product Blister Size

- Features

- Automatic Feeder, Touch Screen Panel, Error Detection

- Power Supply

- AC

- Noise Level

- 75 dB db

- Type

- Flat Forming Blister Machine

- Material

- Stainless Steel

- Feature

- Other

- Auxiliary Packaging Machine Type

- Blister Packaging Machine

- Capacity

- Up to 300 Blisters/Minute Pcs/min

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Power

- 3 kW Watt (w)

- Voltage

- 220V / 380V Volt (v)

- Weight (kg)

- 1200 kg Kilograms (kg)

- Dimension (L*W*H)

- 3200 x 750 x 1600 mm Millimeter (mm)

- Color

- Silver Grey

- Sealing Type

- Heat Sealing

Flat Forming Blister Machines Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 1-30 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Flat Forming Blister Machines

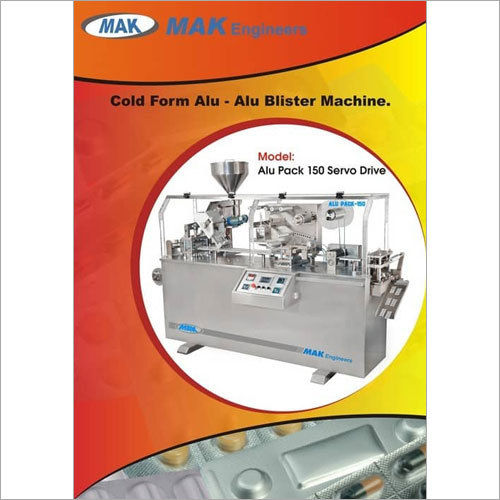

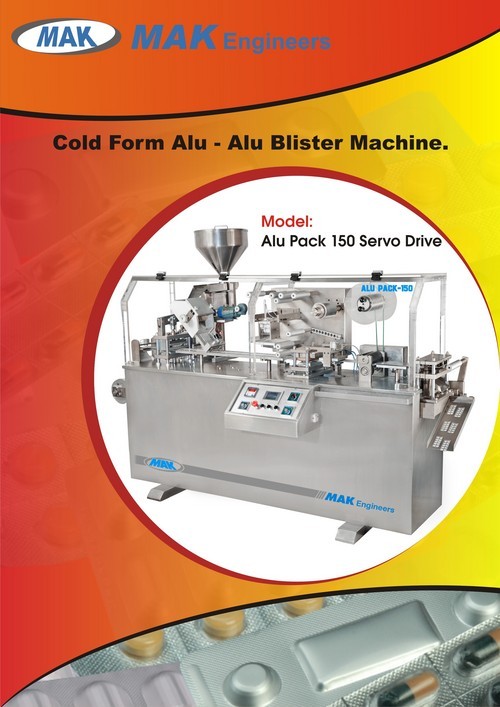

Flat Forming Blister Machine

We are offering Flat Forming Blister Machine. These Flat Forming Blister Machine are offer as per clients specification.Keeping the quality ahead of profits we prepare some of the most important products that are ready to offer their services for a longer period of time. For helping many pharmaceutical industries we have organized ourselves to provide Flat Forming Blister Machine. The whole range of our machines goes through a proper testing and only then they are procured to clients. Our higher production and huge demand has helped us offer the wide variety of Flat Forming Blister Machine in reasonable prices.

Superior Performance for Demanding Industries

Engineered for pharmaceutical, food, and cosmetics applications, this Flat Forming Blister Machine delivers exceptional output and quality. Its computerized, PLC-driven control system ensures high precision and reliability, essential for sensitive product packaging. The machine streamlines operations while maintaining strict hygiene standards demanded by these sectors.

User-Centric Design and Operation

Ease of use is at the core of this blister packaging machine. The touch screen interface allows seamless operation, fast changeovers, and real-time error detection. Whether packaging tablets, capsules, or ampoules, operators benefit from straightforward controls and robust safety features, maximizing productivity and reducing training time.

FAQs of Flat Forming Blister Machines:

Q: How does the Flat Forming Blister Machine achieve high-speed operation?

A: The machine utilizes an advanced PLC control system and electric drive to coordinate automatic feeding, forming, and sealing processes, achieving speeds of up to 300 blisters per minute without compromising precision or product integrity.Q: What products can be packaged with this blister machine?

A: This equipment is versatile, handling blister packaging for tablets, capsules, ampoules, and similar items in the pharmaceutical, food, and cosmetics industries. The filling range adapts based on the blister size required for each product.Q: What is the process involved in blister packaging using this machine?

A: Products are automatically fed into formed blisters, which are then sealed using heat sealing technology. The entire process is controlled via the user-friendly touch screen panel, ensuring precise forming and consistent sealing.Q: When should I consider using a flat forming blister machine?

A: This machine is ideal for businesses requiring reliable, high-speed blister packaging. It is especially suitable when consistent quality, hygienic operation, and the ability to quickly changeover between products are important.Q: Where can this machine be installed?

A: The Flat Forming Blister Machine is suited for installation in manufacturing facilities, packaging plants, and processing units within the pharmaceutical, food, and cosmetic industries. Its compact design allows for integration into existing production lines.Q: What benefits does its PLC control system provide?

A: The PLC (Programmable Logic Controller) system offers precise control over all machine operations, enabling automatic error detection, minimized manual intervention, and enhanced consistency, ultimately reducing downtime and improving product quality.Q: How does the automatic feeder and touch screen panel enhance usage?

A: The automatic feeder ensures continuous product supply to the forming unit, while the touch screen panel provides intuitive operation, real-time monitoring, and quick adjustments, fostering efficient and user-friendly workflow.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Blister Packaging Machines Category

Blister Packaging Machine

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Computerized : Yes

Automatic Grade : Automatic

Control System : PLC Control

Automatic Blister Packaging Machines

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Other, Silver Grey

Computerized : Yes

Automatic Grade : Automatic

Control System : Other, PLC Controlled

Cold Forming Blister Pack Machine

Price 850000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Other, Silver

Computerized : No

Automatic Grade : Automatic

Flat Forming Blister Pack Machine

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Computerized : Yes

Automatic Grade : Automatic

Control System : PLC Control

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS