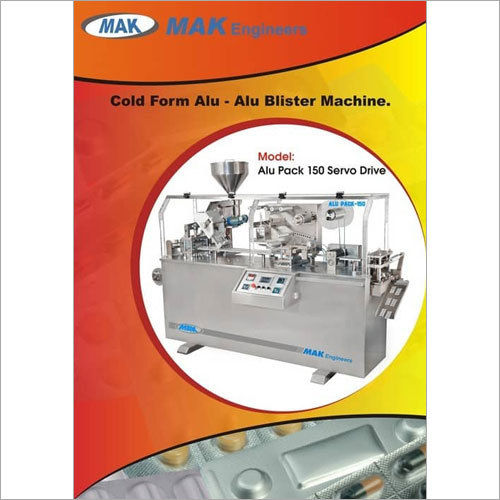

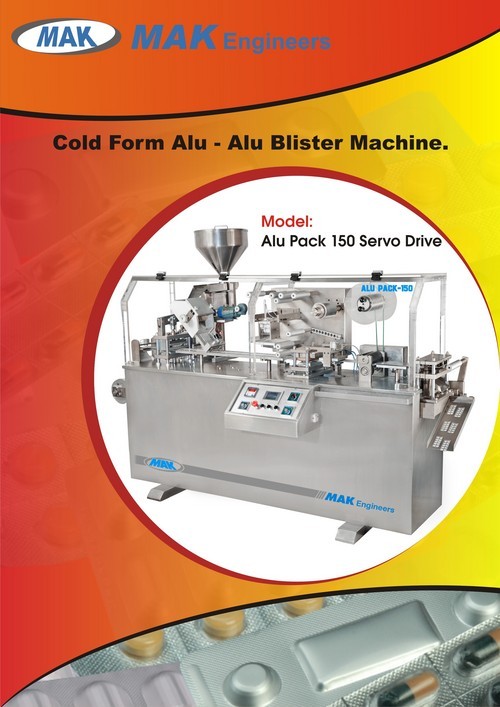

Automatic Blister Packaging Machines

Price 850000.00 INR/ Unit

Automatic Blister Packaging Machines Specification

- Noise Level

- 75 dB

- Application

- Pharmaceutical, Food, Cosmetic, Consumer Goods Packaging

- Power Supply

- AC

- Features

- Touch Screen Operation, Alarm System, Adjustable Speed

- Filling Range

- Customizable

- Usage

- Tablet, Capsule, Softgel, Ampoule, Food Items Packing

- Type

- Automatic Blister Packaging Machine

- Material

- Stainless Steel

- Auxiliary Packaging Machine Type

- Blister Sealing Machine

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Controlled

- Drive Type

- Electric

- Power

- 2.5 kW

- Voltage

- 220/380 V

- Weight (kg)

- 600 kg

- Dimension (L*W*H)

- 2500 mm x 800 mm x 1700 mm

- Color

- Silver Grey

- Sealing Type

- Heat Sealing

Automatic Blister Packaging Machines Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 1-30 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Automatic Blister Packaging Machines

Blister Packaging Machines

We are the leading manufacturer and supplier of blister packaging machines. With a valuable experience of about 20 years we have specialized in designing, engineering and manufacturing of long life equipment with zero maintenance cost and low power consumption. Our range is in great demand due to their robust construction, high efficiency, ease of operation and durability. Our r&d personnel survey the market and accordingly suggest methods on how to further improve the quality of our range of blister packaging machines and precisely meet the changing requirements of our clients. Our robust infrastructure helps us in efficiently meeting the bulk requirements of our clients within a short span of time.

Advanced PLC Control and User-Friendly Design

Equipped with a modern PLC control system and an intuitive touch screen, our Automatic Blister Packaging Machine allows for easy operation and precise parameter adjustment. Its alarm system and adjustable speed features provide responsive feedback and production flexibility.

Versatility Across Multiple Industries

With applications spanning pharmaceuticals, foods, cosmetics, and consumer goods, this blister sealing machine is suited for packaging a wide array of products, including tablets, capsules, ampoules, softgels, and various food items. The filling range is customizable to meet your specific production requirements.

Efficient, Safe, and Durable Construction

Built from high-grade stainless steel, the machine boasts a compact design (2500 x 800 x 1700 mm) and weighs 600 kg. Its electric drive and AC power supply ensure reliable performance, while the heat sealing process delivers secure packaging results. Low noise operation further enhances workplace comfort.

FAQs of Automatic Blister Packaging Machines:

Q: How does the automatic blister packaging machine optimize the packaging process?

A: This machine streamlines packaging with fully automatic operation, precise PLC-controlled settings, adjustable speed, and a touch screen interface, enabling fast and consistent blister sealing for pharmaceuticals, food, cosmetics, and consumer goods.Q: What materials and products can be packed using this machine?

A: The machine is designed to pack items such as tablets, capsules, softgels, ampoules, and various food items, utilizing heat sealing for secure packaging. It can accommodate a customizable filling range to fit specific product types and sizes.Q: When is a blister sealing machine advantageous for manufacturers?

A: A blister sealing machine is especially beneficial when consistent, high-volume packaging is required, such as in pharmaceutical, food, or cosmetics production. Its automation minimizes manual effort, improving efficiency and output quality.Q: Where can this automatic blister packaging machine be installed?

A: Due to its compact design and robust build, the machine suits production facilities, packaging plants, contract manufacturing sites, and supplier operations. It is commonly used in pharmaceutical, food, and consumer goods industries across India and for export.Q: What is the process for using the machine to package items?

A: Operators load the products and packaging materials, set desired parameters via the touch screen, and initiate automated cycles. The machine fills and heat-seals the blisters, with an alarm system monitoring for issues and adjustable speed to suit production needs.Q: How does the PLC control system benefit users?

A: The advanced PLC control system ensures accurate, repeatable operations and easy adjustment of parameters, leading to increased packaging consistency and reduced downtime during changeovers or troubleshooting.Q: What are the key benefits of using this automatic blister packaging machine?

A: Key benefits include high-speed packaging, reduced manual labor, consistent results, safe and hygienic operation due to stainless steel construction, low noise output, and compatibility with a wide range of products and packaging applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Blister Packaging Machines Category

Flat Forming Blister Machines

Price 850000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Color : Other, Silver Grey

Automatic Grade : Automatic

Material : Stainless Steel

Blister Packaging Machine

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Color : Silver

Automatic Grade : Automatic

Material : Stainless Steel

Cold Forming Blister Pack Machine

Price 850000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Color : Other, Silver

Automatic Grade : Automatic

Material : SS

Flat Forming Blister Pack Machine

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Color : Silver

Automatic Grade : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS