Double Track Alu Blister Machine

Price 850000.00 INR/ Unit

Double Track Alu Blister Machine Specification

- Features

- Double Track operation, PLC touch screen, Automatic Feeding, High reliability

- Filling Range

- Customizable

- Application

- Pharmaceutical Tablet and Capsule Packaging

- Power Supply

- Three Phase

- Noise Level

- 75 dB

- Usage

- Pharmaceutical Blister Packing

- Type

- Double Track Alu Blister Machine

- Material

- Stainless Steel

- Feature

- High Speed, Durable, Precision Forming and Sealing

- Auxiliary Packaging Machine Type

- Blister Packaging Machine

- Capacity

- 240-300 blisters/min (approx.)

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control System

- Drive Type

- Electric

- Power

- 4.5 kW

- Voltage

- 220V / 380V, 50Hz

- Weight (kg)

- 1600 kg (approx.)

- Dimension (L*W*H)

- 3150 x 850 x 1900 mm

- Color

- Silver Grey

- Sealing Type

- Aluminium Foil Sealing

- Compressed Air

- 0.5-0.7 MPa

- Feeding Mechanism

- Automatic Vibratory

- Cutting Frequency

- 15-40 times/min

- Main Motor

- Servo Motor Driven

- Film Thickness Range

- 0.15-0.6 mm

- Conforms to GMP Standards

- Yes

- Operation Panel

- Touch Screen HMI

- Safety System

- Emergency Stop and Safety Guard

- Max Forming Area

- 250 x 120 mm

- Cooling System

- Water Chiller or Tap Water

- Blister Forming Depth

- Max 12mm

Double Track Alu Blister Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 1-30 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Double Track Alu Blister Machine

Product Specification

Phase 3 Phase

Voltage 415 V

Brand Mak Engineers

Usage/Application Tablet/ Capsules

I Deal In New Only

Country of Origin Made in India

Minimum Order Quantity 1

Product Description

We are engaged in offering a wide range of Double Track Alu Alu Blister Packing Machine to our clients. Our range of all products is widely appreciated by our clients.

Advanced Double Track Operation

With its double track design, the Alu Blister Machine enables simultaneous processing on two lines, effectively doubling packaging speed and productivity. This design is ideal for high-volume pharmaceutical environments, greatly reducing turnaround times and increasing output without compromising accuracy or product quality. The machine is engineered to streamline production while maintaining GMP standards.

Automated Precision and Control

The automatic vibratory feeding mechanism ensures consistent product alignment, while the PLC-controlled touch screen HMI allows operators to easily adjust and monitor all parameters. Servo motor-driven mechanisms deliver accurate forming, cutting, and sealing. This results in minimal wastage, exceptional packaging precision, and adaptability to different tablet and capsule sizes.

Durable Construction and Safety

Built with stainless steel and designed for continuous operation, this machine prioritizes durability, hygiene, and operator safety. Its safety guard and emergency stop system add crucial protections, and the noise level remains comfortable for long shifts. The option to use a water chiller or tap water for the cooling system further supports consistent, reliable performance in various production settings.

FAQs of Double Track Alu Blister Machine:

Q: How does the Double Track Alu Blister Machine improve pharmaceutical packaging efficiency?

A: The machines dual-track system allows two blister strips to be formed, filled, and sealed simultaneously. This doubles the throughput, enabling a capacity of approximately 240300 blisters per minute, significantly streamlining packaging for large batches.Q: What types of pharmaceutical products can be packaged on this machine?

A: The Double Track Alu Blister Machine is ideal for packaging various sizes of pharmaceutical tablets and capsules. Its adjustable filling range and automatic vibratory feeding system ensure compatibility with a wide array of product shapes and dosages.Q: When should the water chiller or tap water cooling system be used?

A: For high-speed, extended production runs or when working in warmer environments, the water chiller is recommended to maintain optimal forming temperatures. Tap water is suitable for moderate production volumes or when ambient temperatures are controlled.Q: Where is the machine typically installed and operated?

A: This machine is designed for GMP-compliant pharmaceutical manufacturing facilities, including factories, packaging plants, and export-oriented units. Its robust construction makes it suitable for both large and mid-sized operations in India and abroad.Q: What is the process flow of blister packaging with this machine?

A: First, the machine automatically forms the blister cavities with precise depth and size, followed by filling tablets or capsules using the vibratory feeder. The blisters are then sealed with aluminum foil and cut to sizeall through automated, electronically controlled steps.Q: How does the user interface improve operation and maintenance?

A: The touch screen HMI panel provides intuitive control over all machine functions, facilitating rapid setup, real-time monitoring, and easy troubleshooting. Operators can swiftly adjust parameters, review alarms, and maintain high packaging standards with minimal training.Q: What are the key benefits of using this model for pharmaceutical packaging?

A: Key advantages include high-speed operation, excellent sealing quality, compatibility with GMP standards, robust safety features, customizable settings, reduced material wastage, and durable constructionoffering long-term reliability and optimal product integrity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Alu Alu Blister Packing Machine Category

High Speed Alu Alu Machine

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Feature : Other, High Speed, Precision Forming & Sealing, Robust Structure

Computerized : Yes

Automatic Grade : Automatic

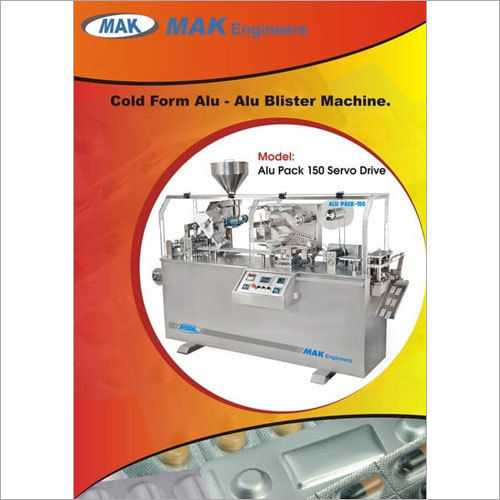

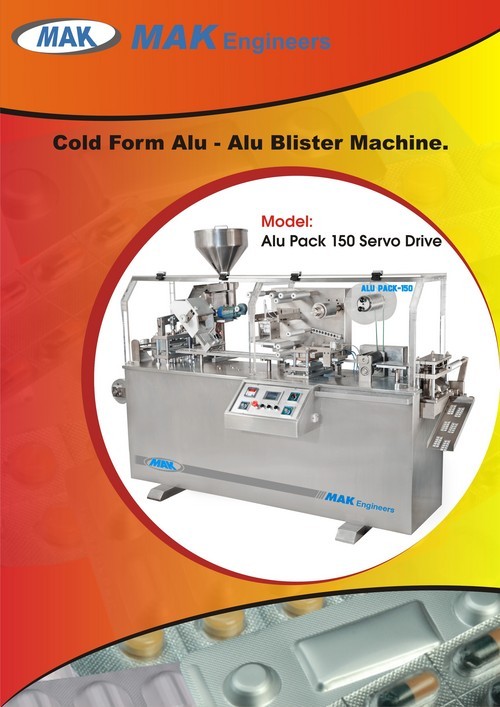

Cold Forming Alu Alu Blister Machine

Price 950000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Feature : Other, Moisture Proof, Leak Proof, Strong Sealing

Computerized : Yes

Automatic Grade : Other, Fully Automatic

PVC ALU Blister Packaging Machine

Price 750000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : SS

Feature : Heavy Duty Machine

Computerized : No

Automatic Grade : Automatic

Alu Alu Blister Packing Machines

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : SS

Feature : Heavy Duty Machine

Computerized : No

Automatic Grade : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS