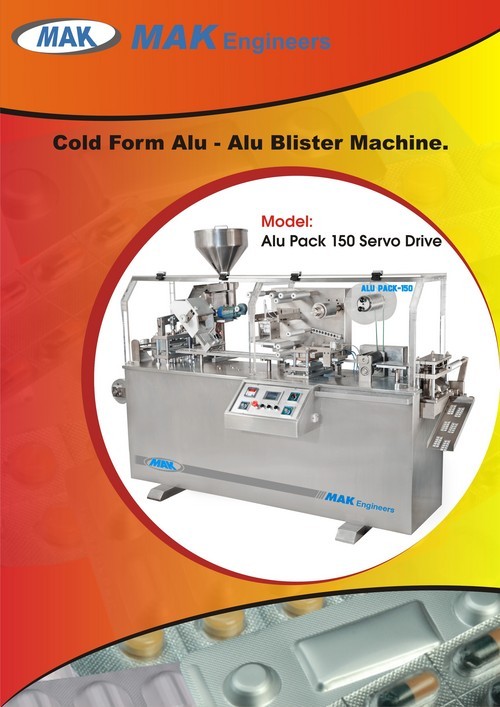

Cold Forming Alu Alu Blister Machine

Price 950000.00 INR/ Unit

Cold Forming Alu Alu Blister Machine Specification

- Noise Level

- Less than 75 dB

- Application

- Pharmaceutical, Food, Chemical Packaging

- Filling Range

- Designed for tablets, capsules, and similar forms

- Features

- Touch Screen Operation, Auto Feeding, High Precision Forming, Fault Alarm System

- Usage

- Pharmaceutical blister packaging

- Power Supply

- Three Phase

- Type

- Cold Forming Alu Alu Blister Machine

- Material

- Stainless Steel

- Feature

- Moisture Proof, Leak Proof, Strong Sealing

- Auxiliary Packaging Machine Type

- Blister Packaging Machine

- Computerized

- Yes

- Automatic Grade

- Fully Automatic

- Control System

- PLC Control with HMI Touch Screen

- Drive Type

- Mechanical

- Power

- 4.5 kW

- Voltage

- 220V/380V 50Hz

- Weight (kg)

- 1200 kg (approx.)

- Dimension (L*W*H)

- 3500 x 720 x 1700 mm

- Color

- Silver

Cold Forming Alu Alu Blister Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units, Unit Per Month

- Delivery Time

- 1-30 Days

About Cold Forming Alu Alu Blister Machine

Cold Forming Alu Alu Blister Machine

We are leading manufacturer and supplier of finest Blister Machines that are useful in various pharmaceutical industries. We have brought our wide range of Cold Forming Alu Alu Blister Machine which is highly useful and capable of offering required production. For keeping the quality of medicines intact it is required to offer them proper, germ free and airtight environment. We due to our enlarged production house and world class warehousing unit are capable of delivering desired quality. At each and every step of manufacturing Cold Forming Alu Alu Blister Machine we ensure that the norms of standards set, are followed. In customized ranges and ideally suited prices our wide variety of Blistering Machines are offered.

Advanced Automated Operation

Equipped with a computerized PLC control system and HMI touch screen, the machine ensures streamlined and precise packaging. Fully automatic features such as auto feeding and fault alarm systems reduce human intervention and increase output efficiency, making it ideal for pharmaceutical production lines.

Robust and Versatile Construction

Constructed from high-grade stainless steel and finished in silver, this Alu Alu Blister Machine is designed for durability and hygienic operation. Its mechanical drive, three-phase power supply, and ability to handle a broad range of tablet and capsule sizes make it versatile for pharmaceutical, food, and chemical packaging.

Exceptional Packaging Quality

The machine provides moisture-proof, leak-proof, and strong sealing for sensitive products, ensuring extended shelf-life and protection. High precision cold forming ensures blister packs maintain product integrity throughout storage and distribution.

FAQs of Cold Forming Alu Alu Blister Machine:

Q: How does the Cold Forming Alu Alu Blister Machine achieve moisture proof and leak proof packaging?

A: This machine utilizes high precision forming and strong sealing mechanisms enabled by its mechanical drive and advanced PLC control. Cold forming with Alu-Alu material creates robust, hermetically sealed blisters that prevent moisture ingress and product leakage.Q: What types of products can be packaged using this blister machine?

A: The machine is specifically designed to package tablets, capsules, and similar solid forms. Its versatile filling range makes it suitable for use in the pharmaceutical, food, and chemical industries.Q: When should this machine be considered for blister packaging operations?

A: This machine is ideal when high-speed, high-precision, and reliable blister packaging is required, particularly for sensitive products that demand tight moisture and leak protection. It is especially beneficial in environments prioritizing automation and fault detection.Q: Where can this Cold Forming Alu Alu Blister Machine be utilized?

A: The machine is suitable for deployment in pharmaceutical manufacturing plants, food processing facilities, chemical packaging lines, or in any setting requiring secure and accurate blister packaging.Q: What is the process flow of operating the machine?

A: Operation involves loading the product and Alu-Alu material into the feeder, followed by automatic cold forming, filling, sealing, and cutting. The PLC with HMI touch screen facilitates monitoring, adjustment, and troubleshooting throughout the cycle.Q: How does the machine ensure operator safety and low noise?

A: With its fault alarm system and well-designed mechanical structure, safety hazards are minimized. The noise level remains below 75 dB, contributing to a safer and more comfortable working environment.Q: What are the benefits of using this automated blister machine for exporters and manufacturers?

A: It enhances efficiency, reduces manual labor, provides consistent high-quality packaging, and protects products from moisture and contamination, making it ideal for export and large-scale production requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Alu Alu Blister Packing Machine Category

Alu Blister Machine

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Material : Stainless Steel

Automatic Grade : Automatic

Drive Type : Electric

PVC ALU Blister Packaging Machine

Price 750000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Material : SS

Automatic Grade : Automatic

Drive Type : Electric

Alu Alu Blister Packing Machines

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Material : SS

Automatic Grade : Automatic

Drive Type : Electric

Alu Blister Packaging Machine

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Material : SS

Automatic Grade : Automatic

Drive Type : Electric

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS