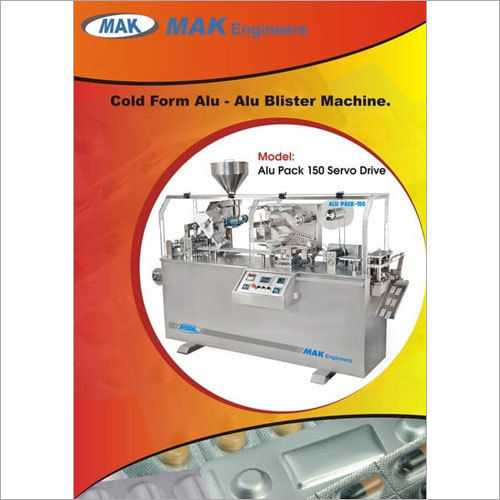

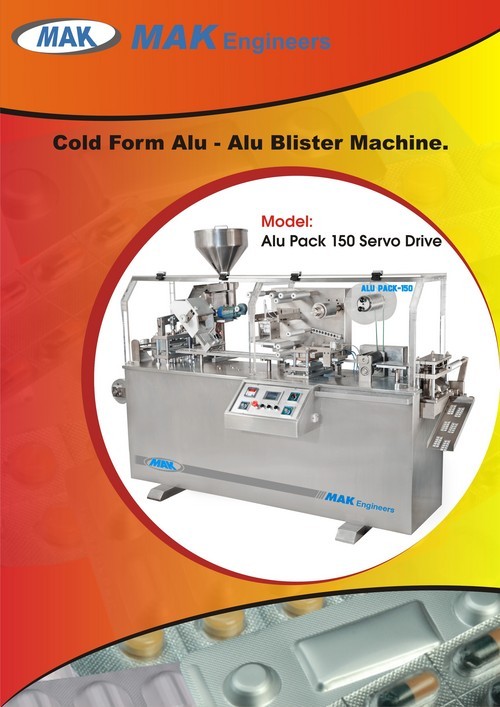

Alu Blister Machine

Price 850000.00 INR/ Unit

Alu Blister Machine Specification

- Power Supply

- AC

- Usage

- Tablet, Capsule, and Softgel Blister Packaging

- Noise Level

- 75 dB db

- Filling Range

- Adjustable

- Application

- Pharmaceutical, Food, Medical Devices Packaging

- Type

- Alu Blister Machine

- Material

- Stainless Steel

- Feature

- Other

- Auxiliary Packaging Machine Type

- Blister Packaging Machine

- Computerized

- Yes

- Automatic Grade

- Automatic

- Drive Type

- Electric

- Power

- 2.5 KW Watt (w)

- Voltage

- 220V/380V, 50/60Hz Volt (v)

- Weight (kg)

- 850 kg Kilograms (kg)

- Dimension (L*W*H)

- 2900 x 850 x 1500 mm Millimeter (mm)

- Color

- Silver / Metallic

Alu Blister Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 1-30 Days

- Sample Available

- Yes

- Main Domestic Market

- All India

About Alu Blister Machine

Alu Alu Blister Machine

Packaging has always been a tricky process and for performing a perfect packaging operation a good quality machine is always required. Understanding the requirements of customers we have brought an extensive range of Alu Alu Blister Machine. This machine is capable of offering the finest packaging facility without interfering the original properties of the product being packed. Mostly for the packaging of medicines where no air is allowed and humidity is required to be zero our Alu Alu Blister Machine is highly applicable. Our astute scientists and engineers keep on bringing forth newer ideas and thus we innovate our ranges to fulfil the requirements of clients.

Advanced Control and Automation

Equipped with a PLC control panel, the Alu Blister Machine ensures seamless automation and accurate packaging management. The computerized interface simplifies operation, reduces human error, and maximizes production efficiency, making it suitable for large-scale manufacturing environments.

High-Speed, Precise Packaging

Engineered for high speed and precision, this machine handles various packaging tasks with remarkable consistency. Its robust construction and electric drive facilitate reliable workflows, while the adjustable filling range addresses the packaging needs of diverse products, from tablets to softgels.

Versatile Application in Critical Industries

The versatile Alu Blister Machine excels in packaging for pharmaceuticals, food, and medical devices, maintaining stringent hygiene and quality standards. Manufacturers benefit from reduced downtime and flexible power compatibility (220V/380V, 50/60Hz), making it a frontrunner for suppliers and exporters in India.

FAQs of Alu Blister Machine:

Q: How does the Alu Blister Machine enhance the packaging process for tablets and capsules?

A: The Alu Blister Machine automates the entire processforming, filling, and sealingusing a precise PLC control system. This reduces manual intervention, increases speed, and ensures that each blister pack meets consistent quality and hygiene standards.Q: What are the primary benefits of using stainless steel in this machines construction?

A: Stainless steel offers exceptional durability, corrosion resistance, and easy cleaning, which are crucial for maintaining hygiene in pharmaceutical and food packaging environments. It also ensures long-lasting performance even in demanding usage scenarios.Q: When is this machine most suitable for use in pharmaceutical packaging lines?

A: The Alu Blister Machine is most beneficial when consistent, high-volume packaging of tablets, capsules, or softgels is required. Its automatic, high-speed operation makes it ideal for both batch and continuous production in pharmaceutical factories.Q: Where can the Alu Blister Machine be installed and operated?

A: This machine is designed for use in hygienic, industrial settings such as pharmaceutical, food, and medical device manufacturing units. Its compact footprint (2900 x 850 x 1500 mm) allows it to fit efficiently into most standard production environments.Q: What is the process of operating the Alu Blister Machine?

A: Operation involves loading the raw materials, configuring the PLC control panel, and setting the desired filling range. The machine then automatically forms blisters, dispenses the product, and seals each pack with minimal supervision, ensuring high speed and accuracy.Q: How does the adjustable filling range benefit the user?

A: The adjustable filling range accommodates different tablet, capsule, and softgel sizes, providing flexibility to manufacture a wide variety of products without changing machines, thus optimizing production lines for multiple product types.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Alu Alu Blister Packing Machine Category

High Speed Alu Alu Machine

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220V/380V

Computerized : Yes

Automatic Grade : Automatic

Drive Type : Electric

Cold Forming Alu Alu Blister Machine

Price 950000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220V/380V 50Hz

Computerized : Yes

Automatic Grade : Other, Fully Automatic

Drive Type : Mechanical

Alu Alu Blister Packing Machines

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220240 Volt (v)

Computerized : No

Automatic Grade : Automatic

Drive Type : Electric

Alu Blister Packaging Machine

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220240 Volt (v)

Computerized : No

Automatic Grade : Automatic

Drive Type : Electric

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS